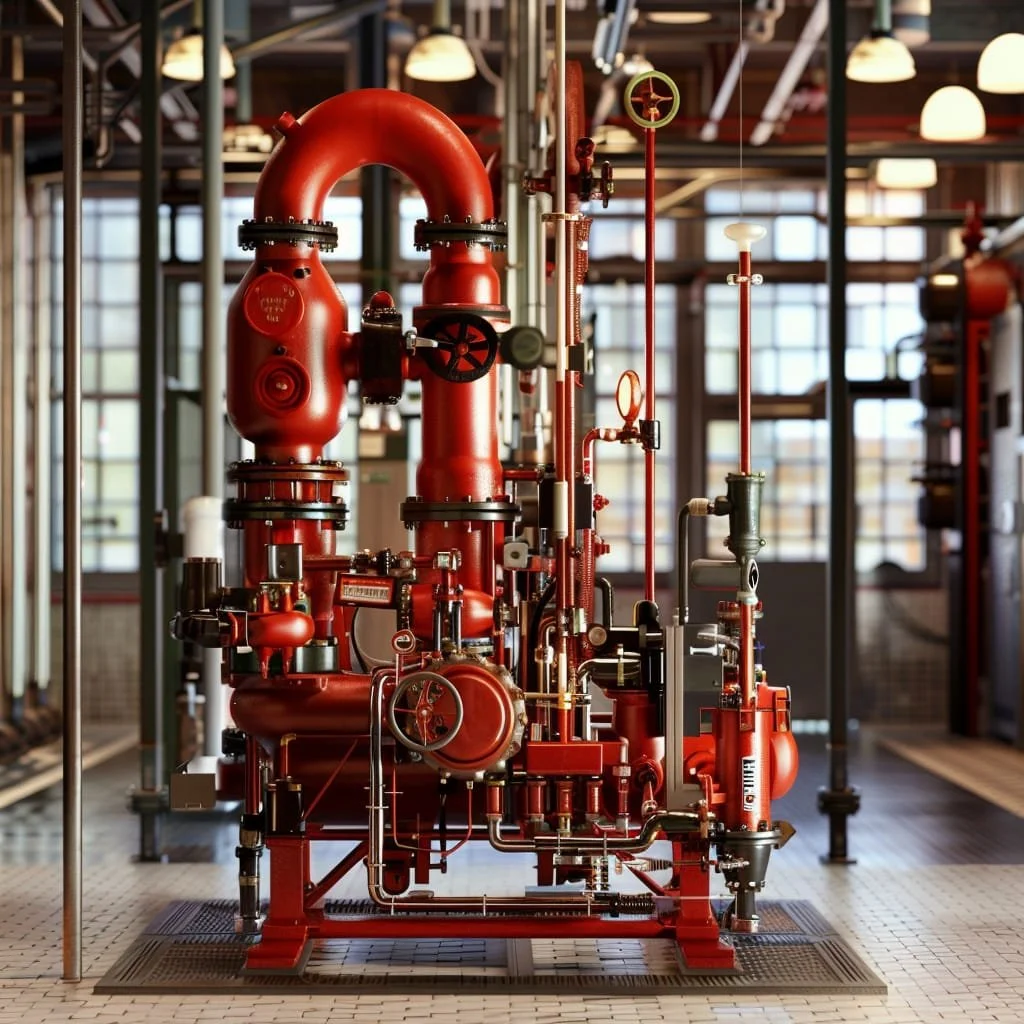

Centrifugal Fire Pumps

Introduction:

Centrifugal fire pumps by FlameShield Fire Systems are engineered for efficiency and reliability in firefighting and emergency water supply applications in the downstream oil and gas sector.

Technical Specifications:

Flow Rate: 50 GPM (11.4 m³/h) to 5000 GPM (1136 m³/h)

Pressure: 50 PSI (3.45 bar) to 300 PSI (20.68 bar)

Materials: Cast iron, stainless steel, bronze

Drive Type: [Electric motor or diesel engine]

Certifications: [List of applicable certifications such as NFPA, UL, FM]

Available Sizes:

[List of available sizes, e.g., 50 GPM (11.4 m³/h), 500 GPM (113 m³/h), 1000 GPM (227 m³/h), 3000 GPM (681 m³/h), 5000 GPM (1136 m³/h)]

Vertical Turbine Fire Pumps

Introduction:

Vertical turbine fire pumps by FlameShield Fire Systems provide high-pressure water supply from deep wells or reservoirs, ideal for demanding oil and gas applications.

Technical Specifications:

Flow Rate: 50 GPM (11.4 m³/h) to 5000 GPM (1136 m³/h)

Pressure: 50 PSI (3.45 bar) to 300 PSI (20.68 bar)

Materials: Cast iron, stainless steel

Drive Type: [Electric motor or diesel engine]

Certifications: [Applicable certifications]

Available Sizes:

[List of available sizes, e.g., 50 GPM (11.4 m³/h), 500 GPM (113 m³/h), 1000 GPM (227 m³/h), 3000 GPM (681 m³/h), 5000 GPM (1136 m³/h)]

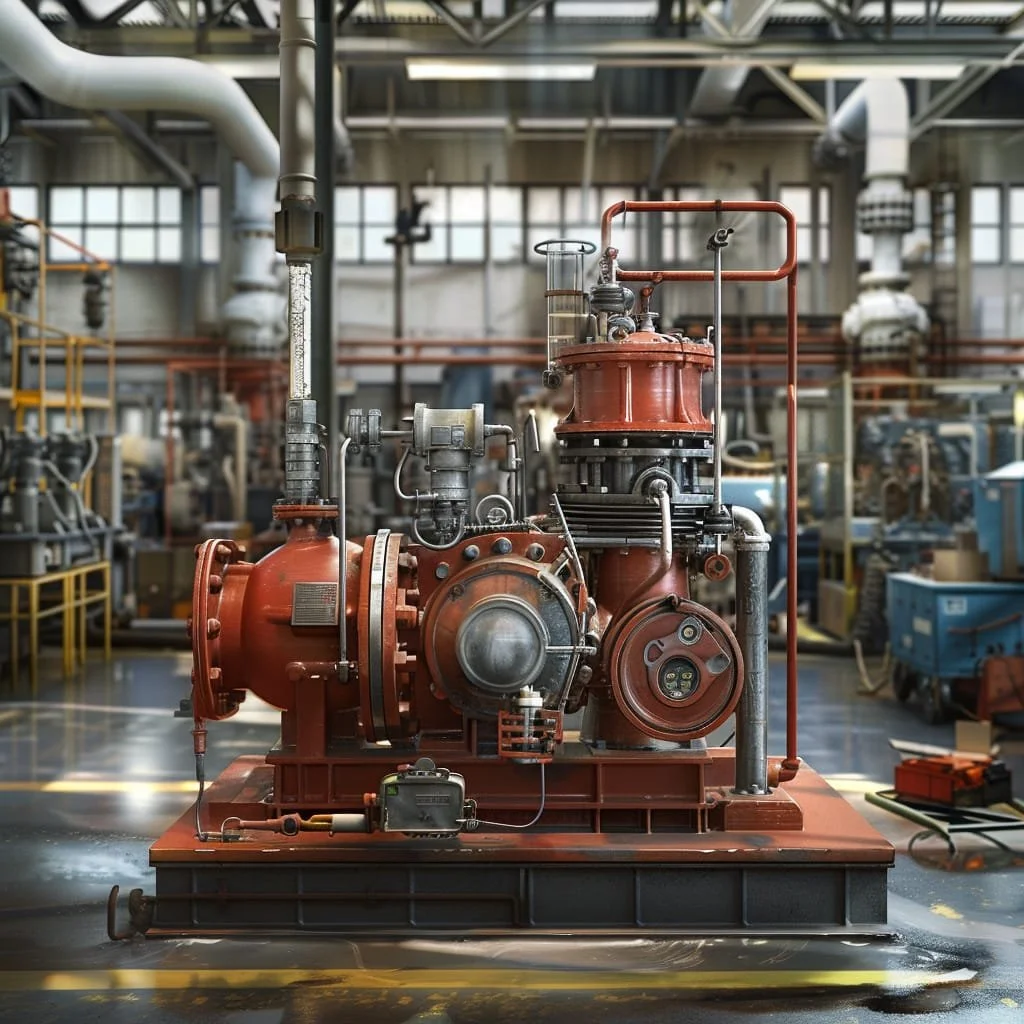

Horizontal Split Case Fire Pumps

Introduction:

Horizontal split case fire pumps by FlameShield Fire Systems offer reliability and ease of maintenance, designed for high flow rates and moderate pressures in industrial and commercial fire protection systems.

Technical Specifications:

Flow Rate: 50 GPM (11.4 m³/h) to 5000 GPM (1136 m³/h)

Pressure: 50 PSI (3.45 bar) to 300 PSI (20.68 bar)

Materials: Cast iron, bronze, stainless steel

Drive Type: [Electric motor or diesel engine]

Certifications: [Applicable certifications]

Available Sizes:

[List of available sizes, e.g., 50 GPM (11.4 m³/h), 500 GPM (113 m³/h), 1000 GPM (227 m³/h), 3000 GPM (681 m³/h), 5000 GPM (1136 m³/h)]

Vertical Inline Fire Pumps

Introduction:

Vertical inline fire pumps by FlameShield Fire Systems are compact and space-efficient, suitable for installations where space is limited. They provide reliable performance in building services and industrial applications.

Technical Specifications:

Flow Rate: 50 GPM (11.4 m³/h) to 5000 GPM (1136 m³/h)

Pressure: 50 PSI (3.45 bar) to 300 PSI (20.68 bar)

Materials: Cast iron, stainless steel

Drive Type: [Electric motor or diesel engine]

Certifications: [Applicable certifications]

Available Sizes:

[List of available sizes, e.g., 50 GPM (11.4 m³/h), 500 GPM (113 m³/h), 1000 GPM (227 m³/h), 3000 GPM (681 m³/h), 5000 GPM (1136 m³/h)]

Lobe Pumps

Introduction:

Lobe pumps are a type of positive displacement pump known for their reliability and efficiency in handling viscous fluids and solids. These pumps are widely used in the oil and gas industry due to their ability to maintain a steady flow rate, even under varying pressure conditions.

General Uses in Oil and Gas Field

Crude Oil Transfer: Efficiently handles the transfer of crude oil and other viscous fluids from one location to another.

Chemical Processing: Ideal for the precise dosing and transfer of chemicals in various stages of oil and gas processing.

Sludge and Slurry Handling: Effective in moving sludge and slurry, often encountered in drilling operations and waste management.

Glycol Circulation: Used in dehydration units to circulate glycol, ensuring the removal of water vapor from natural gas.

Cooling and Heating Systems: Employed in systems where high-viscosity fluids need to be circulated for temperature regulation.

Ranges and Specifications

Flow Rates: 5 to 10,000 GPM

Pressure Ratings: Up to 300 PSI

Temperature Range: -40°F to 350°F

Viscosity Range: 1 to 1,000,000 cSt

Material Construction

To ensure durability and reliability in harsh environments, lobe pumps are constructed using high-quality materials, including:

Stainless Steel: Offers excellent corrosion resistance, ideal for handling aggressive fluids and high-pressure conditions.

Cast Iron: For general-purpose applications, providing a good balance of strength and cost-effectiveness.

Hastelloy: Highly resistant to corrosion and high temperatures, suitable for extreme conditions.

Bronze: Used for specific applications requiring good resistance to saltwater and other corrosive fluids.

Teflon Coatings: Applied for enhanced chemical resistance in highly corrosive environments.

Manufacturing Process

At FlameShield Fire Systems, we design and cast our fire pump models in our state-of-the-art facility located in Houston, TX, USA. Our casting process utilizes the following materials:

Cast Iron

Stainless Steel

Bronze

Each material is selected based on its suitability for different components of our fire pumps, ensuring durability, performance, and reliability in demanding environments.